It all started with a conversation with Bill Lavender at the 2017 SINDAG Convention in Rio Grande do Sul (southern Brazil).

"...Let me introduce you to the Hatfields."

by Lucas Zanoni

At that time, the second generation of the Zanoni family was not yet active in the company and was attending the event as guests of its founders, Sérgio and Graziela. After meeting the AgAir Update team, Lucas (son) and Juliano (son-in-law) asked what they should do to enter the U.S. agricultural aviation market. Bill's first response was, "Come to a barbecue in Georgia and attend the NAAA Convention; that should be your first step." Concerned with regulatory issues and meeting all legal requirements, Sérgio asked the two young men to translate his question: "But can Americans use our products?" Mr. Lavender then gave a response that would have a significant impact on the aerial application technology market on both continents: "I don't know, but there is a family here that will certainly be able to answer that for you. Let me introduce you to the Hatfields".

Lucas and Juliano stopped by the Turbine Conversions booth at that same event. Briefly, they spoke with Ann Grahek (Bill Hatfield's daughter), who invited them to visit the NAAA's Ag Aviation Expo that year in Savannah. By the end of 2017, Sérgio and the two young men decided to attend the event as guests to get a first impression of the industry in North America. Before the exhibition, they visited Perry, where AgAir Update usually hosts its "open hangar" before the Savannah-held NAAA conventions. They experienced an American barbecue for the first time (which, despite profound culinary differences, carries the same spirit as rural Brazilian culture). Then, the three attended the exhibition, meeting the rest of the Hatfield family. Ann Grahek still tells us today that when her father received a Zanoni catalog, his reaction was immediate: "Why didn't American pilots know about this? We need these products here in the U.S.".

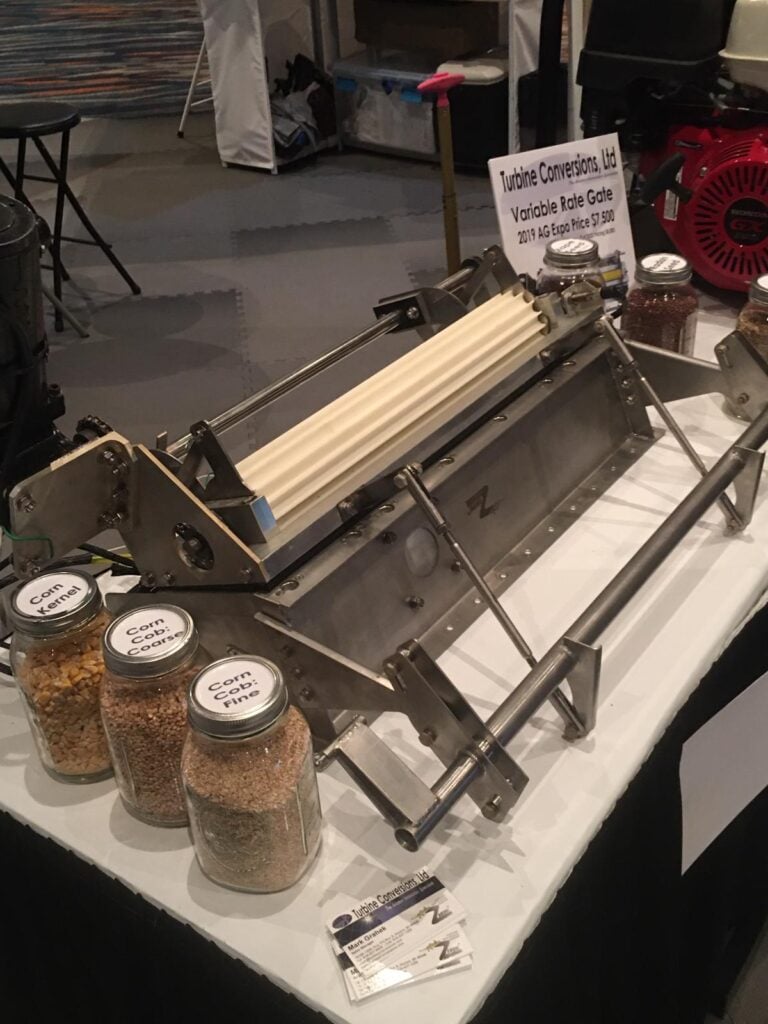

At the beginning of the following year, Turbine requested what would be Zanoni's first product in the U.S.: a Zanoni gate box for the Embraer Ipanema aircraft (the most popular model in Brazil), intended to install their variable-rate system for low solid flow rates. Thus, the partnership between the two companies was born: cooperation between the two largest agricultural aviation markets in the world, focused on development, innovation, and new solutions for aerial application. In mid-2018, the SINDAG convention occurred in Maringá (less than 50 miles from the Zanoni Equipamentos headquarters). Ann and Bill spent several moments at the Brazilian company's booth on that occasion and understood the brand's strength in Brazilian agricultural aviation.

A few months later, Zanoni Equipamentos decided to go a step further and formally participated in the NAAA Convention (this time in Reno) with a booth to showcase its products. Among those curious about the technologies—until then unknown in the American market—were Al Schiffer (Michigan), Ralph Lutes (Indiana), and Al Allen (South Carolina). Al and Ralph, friends of Bill Hatfield, asked him to organize a joint shipment of some products from Brazil to the U.S. By the end of that event, Turbine Conversions invited the Zanoni family to dinner and proposed becoming their agents, representatives, and distributors for North America. Mark Grahek, Ann's husband, would become responsible for all sales and after-sales dealings for Zanoni in the U.S. and Canada.

2018 Convention in Reno, when Zanoni and Turbine agreed on their partnership

Over the past six years, the Turbine-Zanoni partnership has brought several advancements to U.S. agricultural aviation, including (1) new spraying equipment options for the market, (2) a new network of regional dealers to assist operators, (3) new supply chains for the industry, (4) new paradigms in aerial application technologies, and (5) a reminder of how important family values are to our industry.

ALL PHOTOS ABOVE: Zanoni US tour in 2023, where they visited Lutes, Aerinova, Holzwarth, Farm Air, Lindell, Agri-Tech, and ASI Jet

New Spraying Equipment Options for the Market

One of the first comments Zanoni received when entering the U.S. market was: "I don't know if this product is the best option, but we appreciate you entering the market because we need more competition." Already established in South America (where they are installed in over 3,000 agricultural aircraft), Zanoni's spraying components arrived in the U.S. market thanks to curiosity about innovations. Since then, more than a hundred U.S. aircraft have been equipped with

Zanoni pumps, valves, filters, booms, and atomizers are highly accepted because of their durability and customization.

Zanoni's equipment is recognized worldwide for its long lifespan and reliability. The reality in Brazil, vastly different from the U.S., requires aircraft to be equipped with the most resistant parts possible. Many Brazilian operators work in extremely remote areas, sometimes over 1,000 miles from the nearest aircraft maintenance center, where even the delivery of a single screw can take up to a month. Consequently, agricultural aircraft must have components that will not fail "far from civilization". Moreover, Brazil's crop planting system (soybeans followed by cotton or corn in the same field) results in a much longer spraying season than in the U.S., sometimes lasting up to 10 months per year. In some specific regions of Latin America, where fruit plantations exist, applications can occur year-round nearly every week, which places far greater demands on spraying equipment than in areas with shorter spraying seasons. These industry characteristics created a need for parts that could withstand the harshest conditions, a demand that led to the founding of Zanoni Equipamentos in the 1990s.

Beyond equipment with different compositions from what is typically used in the U.S., another factor driving Zanoni's success in North America is its comprehensive customer service. Founded as a company to "solve aerial application problems," Zanoni has a core philosophy of listening and customizing parts according to each customer's needs. The company understands that no two agricultural aviation operations are identical and no one-size-fits-all solution exists. As a result, its engineering team (which now has over 10 professionals) can develop any custom part for a specific service, usually communicated through Mark Grahek, who maintains daily contact with the company in Brazil.

A New Network of Spraying Parts Dealers in North America

In addition to a new product line as an option for those operating in the U.S., the Zanoni-Turbine partnership has brought a new way to access spraying parts. After the agreement, the first concern of both companies was how to ensure the agility that the agricultural aviation sector demands. It was decided that TCL's headquarters in Nunica, Michigan, would serve as the storage hub for a large inventory of parts for the entire Air Tractor and Thrush fleet, as well as some less common aircraft in the U.S., such as the Pawnee, Cessna, and Ag-Cat, to address the agility requirement since then, every year, Zanoni ships a container from Paranavaí (in southern Brazil) to the U.S., filled with complete equipment and repair parts. In addition to scheduled shipments, the logistics system between the two companies also works seamlessly in emergencies. Air courier services can ship some products on a Monday and arrive anywhere in the U.S. before the weekend.

ALL PHOTOS ABOVE: Zanoni US tour in 2024, where they visited Agricair, Heinen Brothers, Reabe, CE-Air, and Air Cover Crop Solutions

After establishing the initial operational structure, Mark Grahek is now focused on expanding the distribution network for spraying parts across North America to ensure even faster access during the season. Turbine-Zanoni already has three regional dealerships: one in Nebraska, one in South Dakota, and one in Canada. Beckman Aircraft Maintenance is an agricultural aircraft maintenance shop serving U.S. Midwest operators. It saw value in having spraying parts readily available for its customers' maintenance needs. The other two dealers were among Zanoni's first customers on the continent and are proof of the quality of its products. Wilde Air Service, based in Brookings, South Dakota, operates Thrush and AT-802 aircraft (equipped with all kinds of Zanoni gear) and now serves as a test company for developments the Brazilian manufacturer is bringing to the U.S. market. Meanwhile, Arty's Air Service, located in the Canadian province of Manitoba, has various Zanoni products installed on its Air Tractors. However, it is primarily beginning to distribute ground-use equipment, such as chemical transfer pumps and line filters.

A New Supply Chain for Aerial Agricultural Technologies

The partnership between Zanoni and Turbine has benefited the American market by distributing Brazilian products in the U.S. and helping position products made in Michigan in other parts of the world. Initially, Zanoni's partnership contributed to introducing the Hatfield family's flagship product, the Single Point Fueling System, to the Brazilian market. Although Zanoni is not the local dealer for this equipment, the company has actively promoted this vital safety tool for aerial application operations, recommending it to over 2,500 agricultural aircraft in Brazil that it services. In other South American countries, Zanoni has also helped to publicize TCL's aircraft piston-to-turbine conversion kits and low-volume solid application variable-rate system.

More recently, Zanoni contributed to establishing a new Turbine Conversions dealership in Africa, where its local dealer (Dellair Aviation Services) now represents the American company. Over the past year, the Zanoni-Turbine partnership has taken another step forward. After an inspection conducted by aeronautical engineer Larry Hatcher, Zanoni began collaborating on improvements to some of TCL's equipment for commercialization in Brazil, particularly the longitudinal gate for firefighting. The two companies have also been working together on other American-origin projects to expand the global distribution of Turbine's technologies.

New Paradigms in Aerial Application Technologies

When Zanoni brought its first rotary atomizer to the NAAA Convention, it quickly became evident that there were significant differences in fundamental application concepts between Brazilian and American agricultural aviation. "We don't use this type of equipment here" were some of the first reactions heard in 2018. Initially, as is common with any Brazilian company facing an unfamiliar market (due to what is often called an "underdog syndrome"), the assumption was that something must be wrong in Brazil. It took a few years to realize that the story was quite different.

At first, the atomizers were used in specialized applications where this technology was already present in the U.S. (but which were almost unknown in Brazil). Mark Grahek led several research projects in the U.S., including wind tunnel evaluations at the UNL Pesticide Application Technology Laboratory (to incorporate atomizers into the control of gypsy moths and spruce budworms in Canadian forests) and field evaluations with agricultural aircraft and twin-engine planes (for mosquito control applications). These scientific projects not only supported the North American industry but are now backing other countries just beginning to develop similar aerial vector control services, such as Brazil.

Despite these specialized applications, one fundamental question remained unanswered: why are rotary atomizers widely used in Brazil but not in the U.S.? After seven years of experience in both markets, the conclusion is that the two countries have profound differences. In the U.S., the temperate climate does not exert as much biological pressure on crops, and aerial herbicide applications are common. In contrast, Brazil's high humidity and temperatures make fungicide and insecticide applications crucial for achieving basic agricultural productivity. While U.S. operations often involve small fields with multiple clients on a single flight, in Brazil, a single pilot may spray one million hectares (2.4 million acres) in a year with just one aircraft.

With this close relationship between the pilot and the crop, combined with fewer regulatory restrictions in Brazil, the country's aerial agricultural industry has developed technologies and techniques for low-volume applications (which are more profitable) with the necessary safety measures. About 2,000 Brazilian aircraft operate with systems for this type of work (using rotary atomizers), the only tools capable of ensuring adequate pest control in tropical environments. While the equipment produces a lower volume median diameter (VMD), it generates a higher Dv10 value than other nozzle models—meaning greater uniformity and fewer droplets prone to drift. In summary, atomizers (combined with other factors like adjuvants and proper meteorological conditions) enable safe and efficient applications with 0.5 to 2 GPA volumes, so much so that several product labels in Brazil are being revised to reflect these parameters.

Despite legitimate concerns in U.S. agricultural aviation regarding drift and efficiency, the Brazilian example has demonstrated the viability of high-coverage applications. Safe and profitable application is possible, provided that proper precautions are taken. In recent years, more and more U.S. operators have begun installing Zanoni atomizers for fungicide and insecticide applications on grain crops. Beyond financing research and training to evaluate the equipment under North American conditions and instruct U.S. pilots, Turbine-Zanoni has closely followed customer results. Not only have these operators reported significant increases in aircraft profitability, but they have also observed higher crop yields in fields treated with these methods compared to those using conventional standards.

Making Our Industry Values Great Again

Finally, another major contribution that these two companies are bringing to U.S. agricultural aviation is the revival of core industry values. More than just a technically successful partnership, the two families have built a deep friendship. Members of the Hatfield-Grahek family have visited Paraná multiple times, while the Zanonis have also made several trips to Michigan, always sharing good barbecues, good drinks, and great stories. The two families have even traveled together, covering over 1,500 miles through southern Brazil to Uruguay and going on a safari in South Africa. Mark and Ann Grahek even attended the wedding of one of the Zanoni family members.

This close-knit family relationship has practical outcomes and has been one of the key factors behind the partnership's success. Both companies are driven by ethical work and trust in their customers and friends. Unlike large corporations, any customer has direct access to the people they need to talk to, and both companies are always open to feedback. This human connection enables agile, customized solutions tailored to the specific needs of agricultural aviation, fostering long-term relationships built on trust and transparency. Zanoni and Turbine Conversions will continue, for many years to come, keeping our industry great.