I knew you had trouble when you walked in. Sorry, I couldn’t help that; it’s a little Taylor Swift dad joke. I thought my daughters could appreciate that. When it comes to trouble, I usually don’t have any issues finding it, but when it comes to troubleshooting, I try to use a very commonsense approach, and there are some key things to keep in mind when an issue pops up.

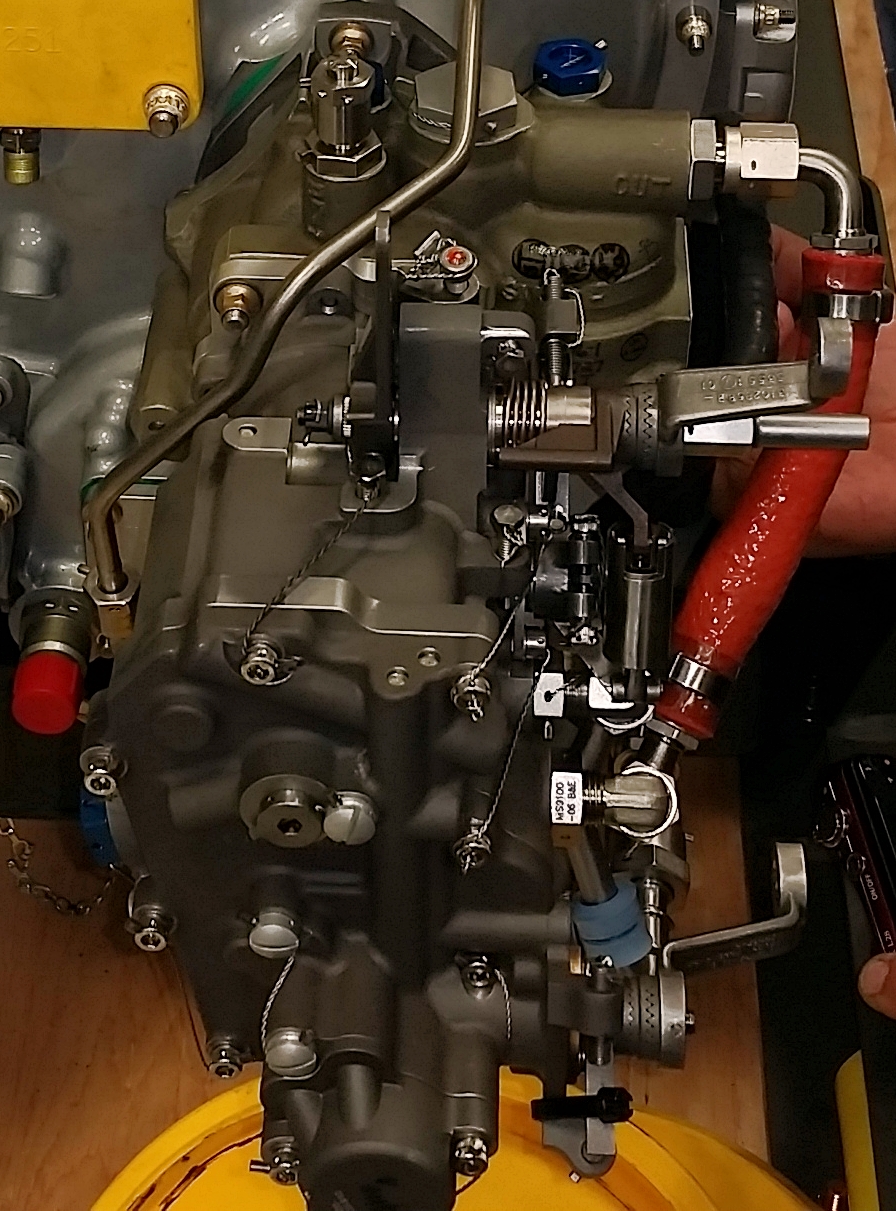

There is some guidance spread through the engine maintenance manual that will help you when you have a problem. There are also some resources available to you that you can utilize. Pratt & Whitney Canada provides you with C-First, a 24-hour global service. There also is a worldwide network of customer support managers available. If you don’t know your service manager, I encourage you to find and meet them. They are there to help you and have been an enormous value to me over the years. Also available is the global service network; this is where Covington Aircraft Engines is your partner resource with Pratt & Whitney Canada. That is quite a network of people available if you have a question.

One of the key things you will need is to identify and communicate the problems you are having. This is where a little information goes a long way. I get a wide variety of calls for various issues that arise. Engines are running “hot” or not making power. Oil pressure is low or high. The prop is surging. One of the great parts of my job is not knowing what the day (or night) will bring. We must discuss the indicating systems and how the issue showed up. This will help with the direction.

As stated in the beginning, I use a commonsense approach to finding issues. If, for instance, you had maintenance done and something changed in your engine performance. I always start with what changed between the engine running good and now. Was there an adjustment made? Was there a filter changed? What might have led me to where I am?

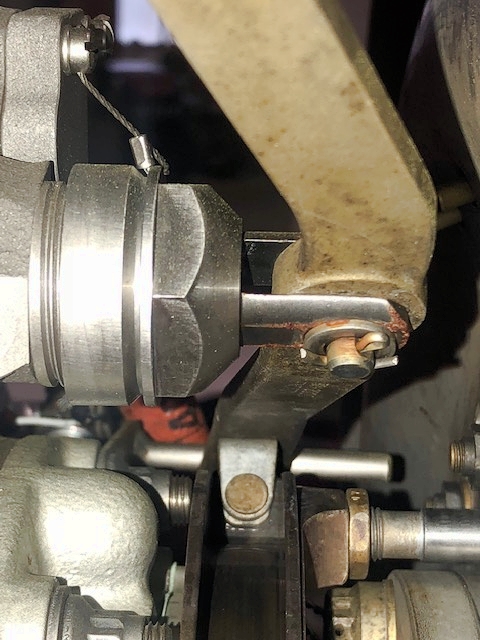

Let’s start with the oil system. Oil system problems usually occur in one of two ways: pressure or temperature. If you have oil pressure problems (i.e., low pressure, high pressure or fluctuations), the first step is to check the oil level and indicating system. The oil filter can influence pressure. For oil temperature issues, we must consider the oil cooler, cooler fans and how much time is spent running the engine with the prop feathered. These are the simple things to check before jumping into the engine internals for problems.

Oil pressure can also influence the torque system. If you are having lower or higher torque issues, you want to ensure that the oil pressure is not the problem. A faulty torque system indication can often make all engine parameters read higher or lower than normal. This is easy to understand because you set everything off the torque reference. You always want to check the indicating system to verify that what you see is accurate.

Another indicating system is engine internal temperature. From a maintenance perspective, we call this the T-5 system or I.T.T., the name comes from where the temperature is measured within the engine. Again, the first step is to verify the indicating system. We may see higher or lower T-5, erratic or even no indication. Keep in mind that T-5 problems will affect temperature only. The problem may not be the internal temperature system if other parameters are also off.

The hot section or compressor (cold) section of your engine can have problems that could change the T-5 or torque systems. For instance, if you are having a hot section issue, it will typically lower compressor speed (Ng). This may not always be the case; that would be too easy. In most cases, this does happen, as well as a rise in T-5 and fuel consumption. Cold section problems will typically raise Ng along with I.T.T. and fuel flow.

Operationally, we also must check the fuel control and propeller. Surging issues or parameter fluctuations typically fall into this category. We want to ensure and do as much testing and investigation as possible. Some of these components can be very expensive, so identifying the problem is critical to spending money as wisely as possible. Many conversations have started with “I have a fuel control problem,” only to find out it was something else. I would suggest never just throwing money at the engine and seeing if it fixes it.

If you need help, I encourage everyone to reach out and use the resources you have at your disposal. Finding and fixing problems gives many of us a tremendous sense of satisfaction. Remember the opening line to the Taylor Swift song that I started this article with, “Once upon a time, a few mistakes ago.” Hopefully, we can all avoid making some of those mistakes by using the tools you have.

Robert Craymer has worked on PT6A engines and PT6A-powered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and has been an instructor of PT6A Maintenance and Familiarization courses for pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member. Robert can be reached at robertc@covingtonaircraft.com or 662-910-9899. Visit us at covingtonaircraft.com.