By Alan McCracken

Yes, Less product on the ground and in the air.*

Every hunter knows the importance of the right weapon and the need for suitable ammunition, which differ significantly whether hunting pigeons or wild boar. The same logic applies to achieving the best results with the application of agrochemicals: it is necessary to adjust the droplet size and the product concentration to match the target.

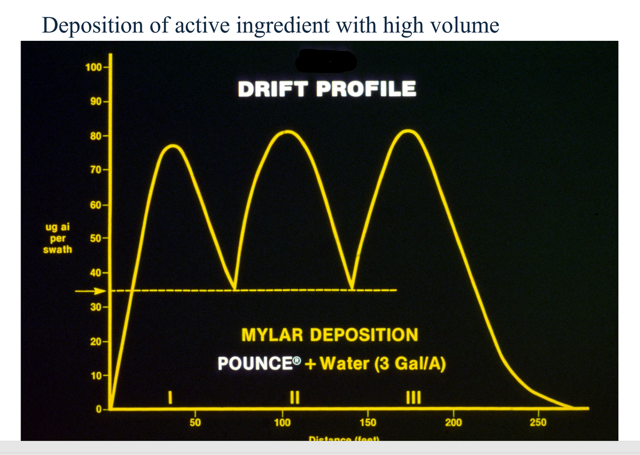

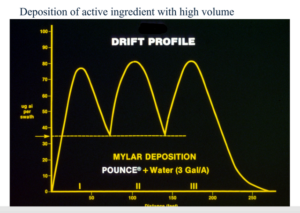

On numerous occasions, on multiple crops using low volumes, my clients have obtained superior pest and disease control using less active ingredients combined with ideal droplet size and oils/adjuvants to protect the droplet size. With low volume application, it is common to obtain a deposit of 100% more chemicals on the crop than with high volume, which raises the question -where did the product disappear to? The answer should concern everyone who thinks about the environment as a product is lost due to “run-off” with large droplets and water evaporation, resulting in off-target drift.

All my professional life has been devoted to obtaining the best results possible with agricultural chemicals, with the only objective being to deliver the product to the target. For those who do not know me, I have worked in over 100 countries and am familiar with practically all commercial crops. I can state that ALL chemical products are more effective when applied to the crop using the minimum water possible. From an application technology standpoint, no crops need a spray volume of more than 1.0 GPA. The only instances when it is necessary to use higher volumes are to apply high volumes of foliar fertilizer-type products.

Technical agronomists frequently publish information that can only be described as absurd, stating that it is physically impossible to obtain adequate coverage per acre using low volumes. Additionally, it’s important to clarify that ground area is only relevant when applying pre-emergent herbicides. In all other instances, the products must be applied to the crops with a minimum or NONE reaching the ground.

Suggestions:

- Mosquito control using aircraft and drones equipped with rotary atomizers to apply pure products with volumes as low as 2.5 fl. ozs per acre to control adults in flight.

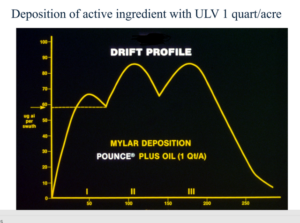

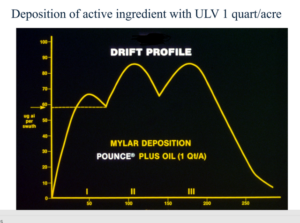

- Locust control in many countries for over 50 years using [ULV] ultra-low volume applications of 1 quart/acre or less under high temperatures and low humidities.

- Cotton Boll Weevil: It has practically been eliminated in the USA through the use of ULV, Ultra Low Volume application of only 1 quart or less per acre, using pure chemicals or products diluted with oil.

- Control of spruce budworm on trees 60ft tall or more using 1 quart per acre.

- Aerial applicators in Argentina/Brazil have successfully used low volumes of 0.3-1.0 GPA for 50 years on multiple crops, including wheat, cotton, citrus, corn, peanuts, potatoes, and soybeans.

- Today, a fleet of over 2,500 ag aircraft operates in Brazil, with over 2000 equipped with rotary atomizers for the application of insecticides and fungicides at spray volumes under 1.0 GPA.

- Each year, an increasing number of large farms in Brazil are moving away from ground applications to obtain consistently better applications with aircraft applying low volumes and to eliminate ground compaction and productivity loss due to crop damage.

Advantages of low volumes include:

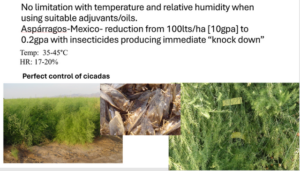

- Free from evaporation problems, high temperatures, and low humidity is no longer an issue.

- Reduction in spray drift since droplets do NOT evaporate.

- Better coverage and crop penetration with more uniform smaller droplets

- Improved control of pests/diseases, with rapid knockdown of pests

- Can normally increase the interval between sprays, with a reduction of 1-2 applications per crop cycle.

- Higher productivity as a consequence of better control of pests and diseases.

- The aircraft sprays more acres per hour in ideal conditions with wind.

When applied in low volumes, herbicides such as glyphosate work faster and produce fewer resistant plants. Thanks to its high product density of 1.25 and low volatility, glyphosate also produces less drift. Numerous clients have proven that the best way to minimize drift with glyphosate is to use low volumes with a maximum of 1 GPA and NOT high volumes.

Key steps to success:

- Correct installation and calibration of suitable equipment that will produce a controlled and more uniform droplet spectrum.

- Apply the products undiluted or with the lowest volume, which is technically possible, using as little water as possible.

- Add suitable oils/adjuvants to protect against evaporation loss and increase the dispersion of the droplets on the target by keeping the droplet wet for a minimum of 5 minutes under conditions of high temperatures and low humidity.

- Never fly without adding products to control evaporation. [Proven for 50 years in South America]

- To ensure good coverage and penetration, only spray when there is a crosswind of at least 2mph [3kph].

- Implement technical training for the pilots and ground support teams.

Adding to the Discussion: The Perspective of Sustainability and Efficiency

If we reduce the spray volume on a farm of 1000 acres from 5GPA to 1GPA, we have an immediate economy of 4000 gallons, resulting in water savings. For cotton or other crops, it is sometimes necessary to make multiple applications, bringing even greater economy.

The productivity may increase from 109 has/hour to 164has/hour. In practice, I have often witnessed a turbine aircraft spraying as much as 340 hectares/840 acres in 45 minutes when the field is near an airstrip.

The 4,000 gallons of water saved through this practice underscore the importance of adopting agricultural methods that respect sustainable water use and contribute to environmental sustainability by minimizing the potential for runoff and contamination of water sources.

Fewer refills result in significant savings in time and resources, including reducing fuel use and decreasing the carbon footprint of agricultural operations. These aspects highlight the relevance of precise and controlled application practices.

Reducing input and operational costs directly reflects the economic sustainability of agricultural operations. Fewer inputs mean lower costs, which can improve farmers’ operational profit margins.

This analysis highlights the urgent need to review traditional agricultural practices in favor of more sustainable methods. Adopting low-volume spraying techniques not only promotes the reduction of wastage of valuable resources, such as water and agrochemicals but also demonstrates the possibility of achieving superior pest and disease control coupled with less environmental impact. This approach, aligned with precise application technologies and fine adjustments in management practices, can lead to a more sustainable and productive agricultural future.

The concept of reducing spray drift and environmental contamination by increasing droplet size and using high volumes, which originated in Europe and then spread to the USA, has been proven ineffective.

Firstly, aerial applications were banned because ground equipment provided more precise applications. The second step was to increase droplet size and spray volume using air induction nozzles to reduce the number of fine drift-prone droplets. In most parts of Europe, the labels demand spray volumes up to 40GPA on wheat and potatoes using ground equipment. I have numerous clients spraying potatoes with excellent pest and disease control using only 1GPA.

This concept has backfired in Europe, where problems with soil and water contamination are due to high-volume spraying.

The current product labels need to be revised to emphasize delivering the product to the “target” rather than the current idea of ZERO drift, which results in poor efficacy and increased soil contamination. In many instances, 50% or more of the product is wasted due to being applied using very high volumes of water.

As an agronomist and mechanical engineer, combined with my passion for agriculture and aerial applications, I kindly suggest that technical agronomists and others make a clear stop with current thinking and review what has been proven for over 50 years.

It’s time for a change to obtain better results and protect the agricultural industry before we are mandated to eat industrially produced worms instead of good beef.

Apply pressure on the chemical companies and regulators to change the labels and implement sound technical solutions instead of repeating the old, outdated idea that increasing droplet size and water volumes control drift.

In all cases, aerial applications using oil or special adjuvants have proven very effective, with minimal product on the ground.