Most of the articles I have presented are focused on best practices. I can share the information, but it is up to each engine owner to do what they want with it. All I can do is lay out a path for success. When things start to go in the wrong direction, there are usually warning signs or signals that indicate a problem is on the horizon.

The PT6A engine has systems to provide some of these warning signs, and I hope everyone here is always listening and looking for them. I have always said the engine will tell you what it wants and what it needs. For example, if you overservice the oil, the engine will push out what it doesn’t want.

Many warning signs of potential problems involve performance. When an engine starts to run at a higher Ng, it could be a signal that it is time for a filter change or a compressor wash. The engine is having to work harder to breathe. A good compressor wash and making sure the filtration system is clean will usually solve that issue.

Another warning signal may be an elevated ITT. If suddenly you cannot get the torque out of the engine you usually have because you are limited by that ITT redline, it could indicate a problem. The engine runs a trim stick, a resistor in the internal turbine temperature system. Occasionally, the resistor may have an issue and not provide the correct resistance. Check it with an OHM meter and verify the proper resistance measurement. You will be back in business. Another item this type of warning signal could be pointing to is distress in the hot section. It will take a borescope of the engine to determine if this is where the issue is. We want to ensure there hasn’t been a tip rub causing a loss of efficiency.

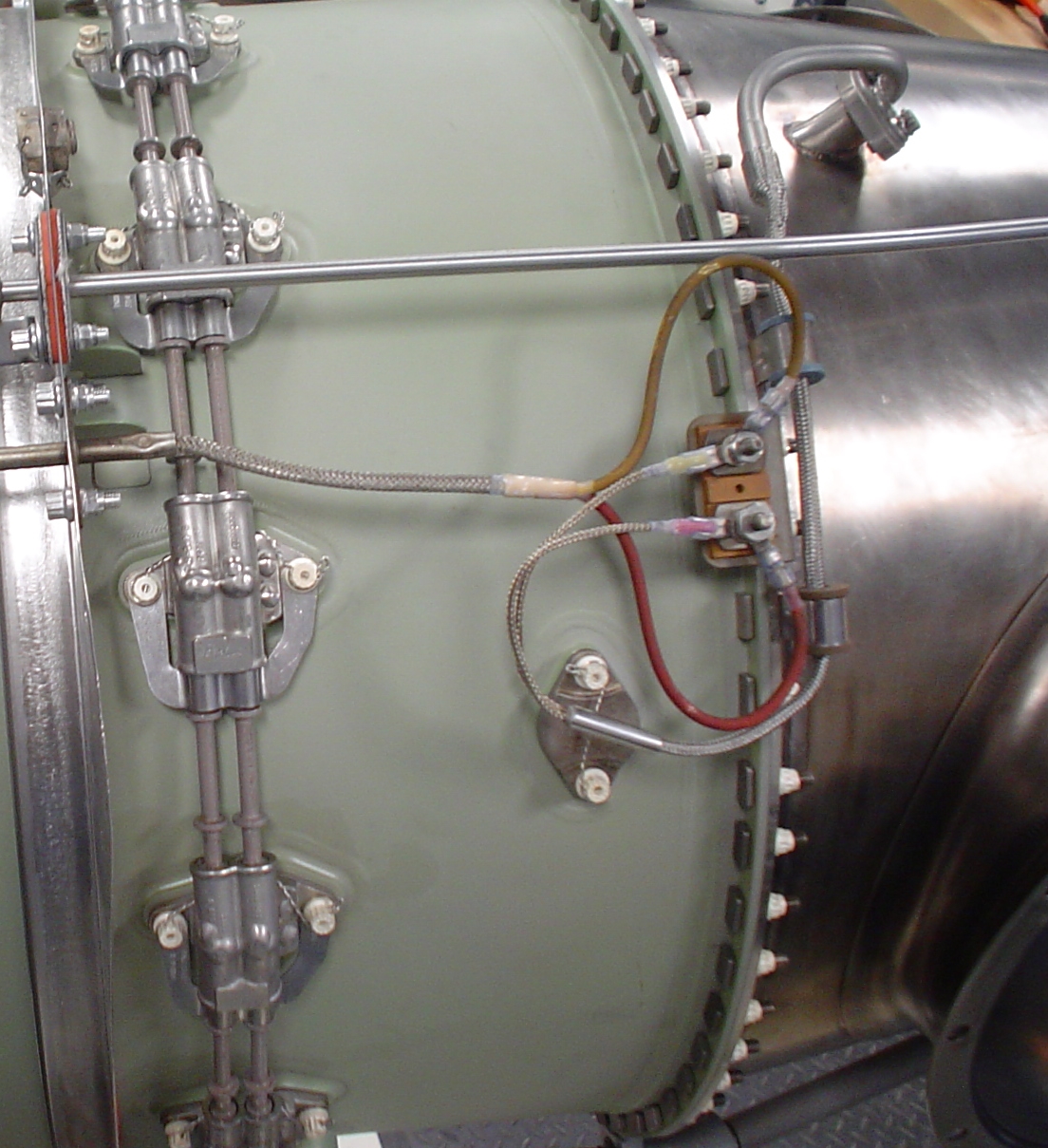

I have had several conversations lately about another warning signal, the chip light. The engine has either one or two chip detectors installed, depending on the model. These chip detectors are simple in nature. They have two magnetic poles and when a ferrous piece of material comes in contact with both a bridge is formed and sends a signal to the cockpit illuminating a light. This is a warning that something needs investigating. This is a warning that you do not want to ignore. Ferrous metal most typically comes from gears or bearings. If this is the problem, you want to get that addressed.

One thing that happens from time to time on new or recently worked engines is a chip light. Again, need to investigate it, but it can be a common occurrence. Many locking features inside the engine must be mechanically set. That is a fancy way of saying bent into position. When this occurs, a small sliver of metal may be created. Although we are always mindful of looking for things like this, we don’t always catch them. Even at new manufacture I have seen this happen. The maintenance manual has directions if you find something on the chip detector.

The maintenance manual will guide you through a decision chart based on what you find. For some debris, you will be asked to check the chip detector and oil filter for hours. You will then, based on the results, be directed to check it again down the road. I bring this up because I had a customer who asked me if I would advise leaving some fine material on the chip detector. His mechanic thought they could gage more clearly if the engine produced additional material. I suggested cleaning the chip detector and checking the oil screen per the maintenance manual requirements. I can’t see a benefit of leaving material on the chip detector.

I hope no one ever has to deal with any of these warning signs, but my caution to everyone is to always listen to their engine. It will tell you if it needs something or if something is going wrong.

Robert Craymer has worked on PT6A engines and PT6A-powered aircraft for the past three decades, including the last 25+ years at Covington Aircraft. As a licensed A&P mechanic, Robert has held every job in an engine overhaul shop and is an instructor of PT6A Maintenance and Familiarization courses for both pilots and mechanics. Robert has been elected to the NAAA board as the Allied-Propulsion Board Member. Robert can be reached at robertc@covingtonaircraft.com or 662-910-9899. Visit us at covingtonaircraft.com.